FUJITOKU is introducing our new line of internally developed products. High level technical capabilities were used in product development to anticipate market needs, while keeping safety and the environment top of mind to create ultimate customer satisfaction.

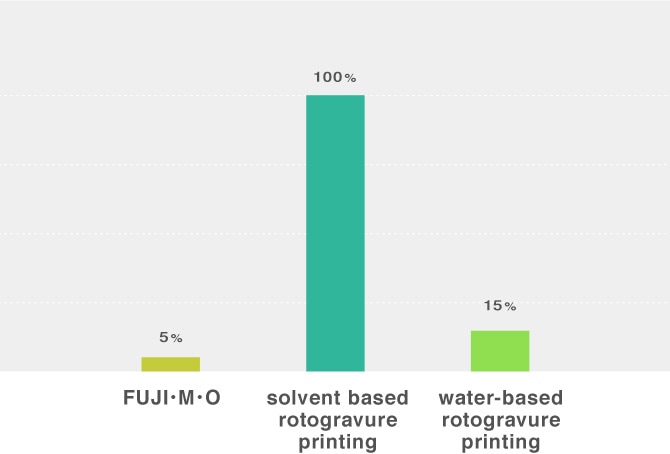

Comparison of residual solvent

between the same printing jobs

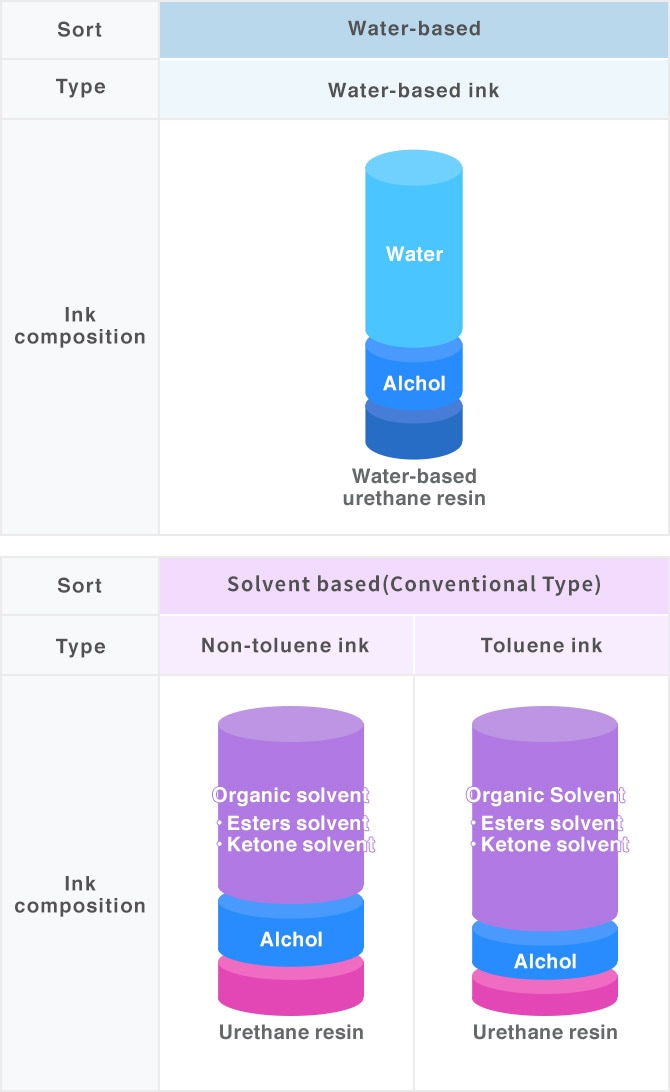

Rough comparison between types of ink

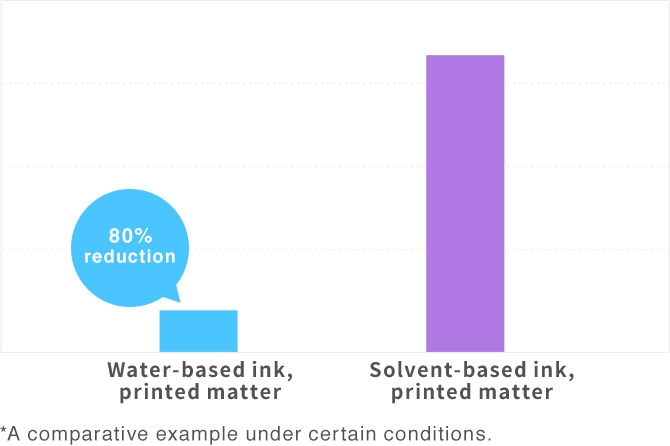

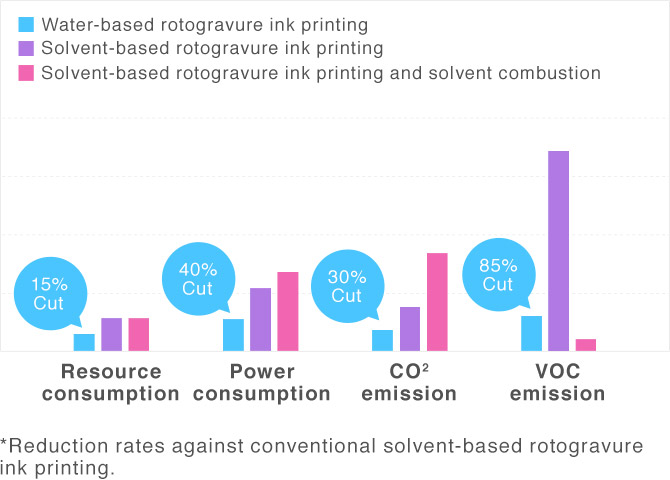

Comparison of environmental burden by LCA

(from ink manufacturing to printing process)

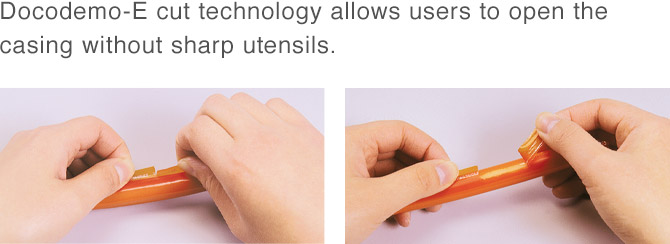

Easy-open feature

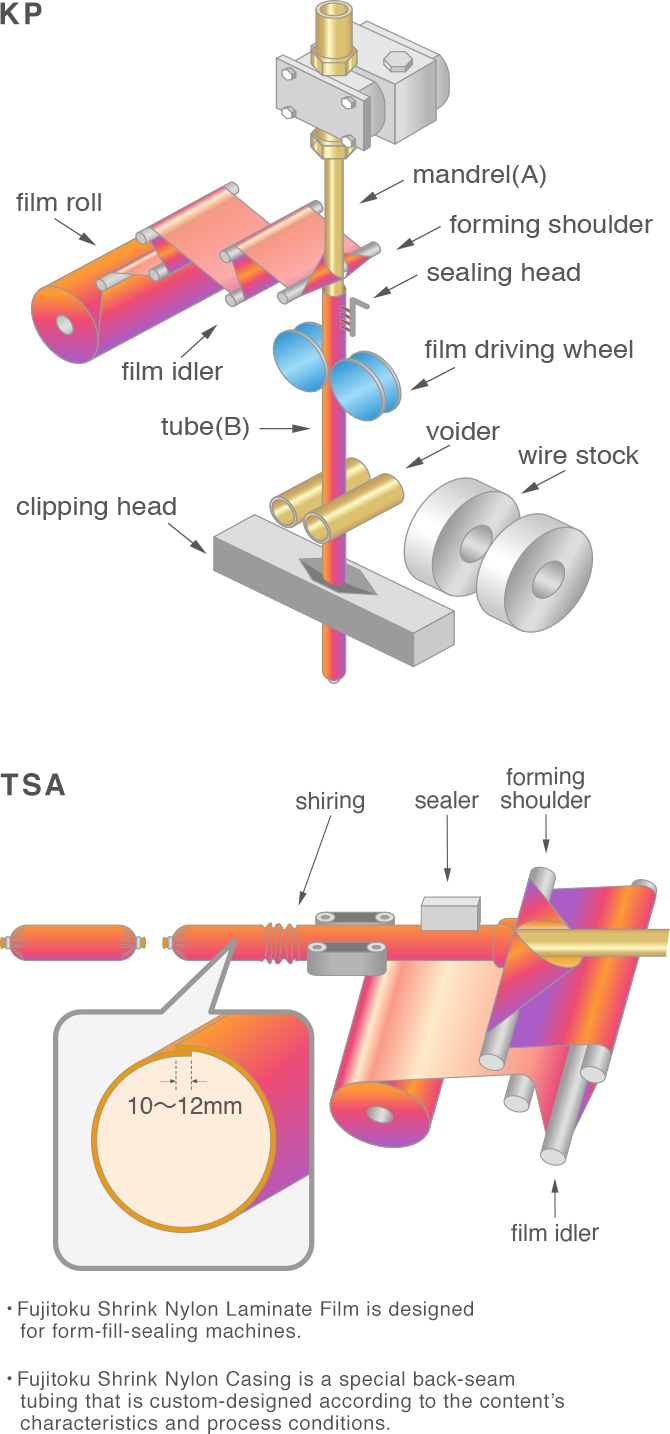

This product line will offer optimal structures for various applications including retort, high-temperature and/or low-temperature sterilization, refrigeration and freezing and will satisfy most technical requirements such as barrier and anti-puncture properties.

This product is designed to be user-friendly and is available for both bag-making machines and FFS (form-fill-seal) machines.

Type

TZ-PE:applicable to polyethylene

TZ-PP:applicable to polypropylene

Graphics can be designed for company logos, product names or other designs to be printed on the flange by reverse printing the three layer laminated film.

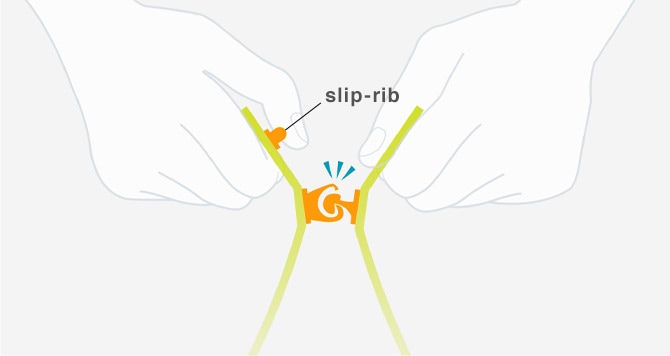

Easy Open Feature

This unique slip rib above the zipper profile allows users to easily locate the zipper and open the pouch.

This technology enables pillow packages to be opened horizontally across the overwrapped sealing area without spilling the contents or spoiling any part of printed information. Smart-Cut zipper pouch, or a combination of Smart-Cut and Zipper will improve functionality of pillow pouches.

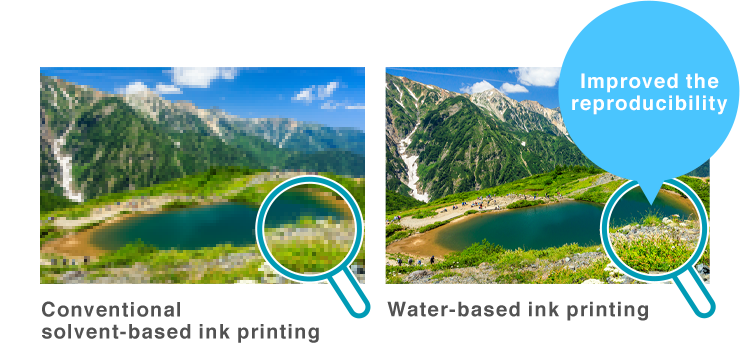

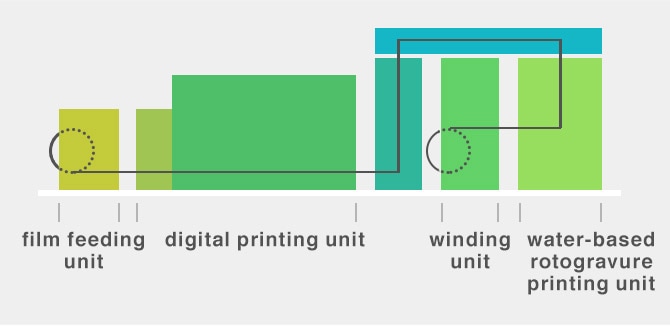

This is a unique press with a combination of high definition digital printing and rotogravure printing with high density white color. This world's first unique press enables Fujitoku to reduce VOC's compared to other water-based rotogravure printing. It also works for well for small lot production.

Structure

VOC consumption